The Dawn of the Blue-Collar Knowledge Worker

AI May Be Taking Your Job, But It's Not Taking Mine.

The conversation about the future of work is dominated by a single, pervasive fear: that artificial intelligence will render human jobs obsolete. The scale of this disruption is a matter of intense debate, but for many professions, the anxiety is no less real. But a different story is unfolding where the digital world meets the pipes, concrete, and steel America was built on. In these foundational sectors, we're not witnessing the replacement of workers, but their evolution. This is the dawn of the Blue-Collar Knowledge Worker, and it provides a powerful blueprint for the next generation of America's skilled trades.

Forging a New Professional Identity

This new professional identity isn't emerging by accident. It's the result of a deliberate shift in how industry leaders view the relationship between technology, training, and talent. This new worker is defined by three core principles:

A Digital-First Mindset: This is built on the concept of the "Digital Worker," a term powerfully articulated in the white paper of the same name by Catherine Curtis, Robert Scott, and Michael Kushner of the organization BAYWORK. It's not a replacement for the skilled tradesperson, but their next evolution. It represents a fundamental shift in professional identity, where value is defined by the ability to seamlessly merge hands-on expertise with digital tools. The nature of the work itself is transforming from reactive to predictive. The old model was driven by crisis: a machine breaks, an alarm sounds, and a crew scrambles to fix it. The new model is driven by curiosity and analysis. The Digital Worker doesn't wait for failure. Instead, they use a tablet or mobile device to monitor real-time data streams, looking for subtle deviations from the baseline. They're not just fixing pumps; they're interpreting trend data to understand why a pump's vibration signature has changed by a fraction of a percent, allowing them to schedule maintenance before the catastrophic failure ever occurs. This proactive approach demands a new set of skills. Traditional mechanical aptitude remains essential, but it must be paired with strong digital literacy and analytical capabilities. It requires an ability to interpret data, understand the basics of sensor technology, and see the physical asset and its "digital twin" as a single, integrated system. The toolbox is evolving. It still contains the classic wrenches and gauges, but now it includes tablets and data dashboards—tools forged in the heart of America's tech revolution—that serve as windows into the very nervous system of the machinery.

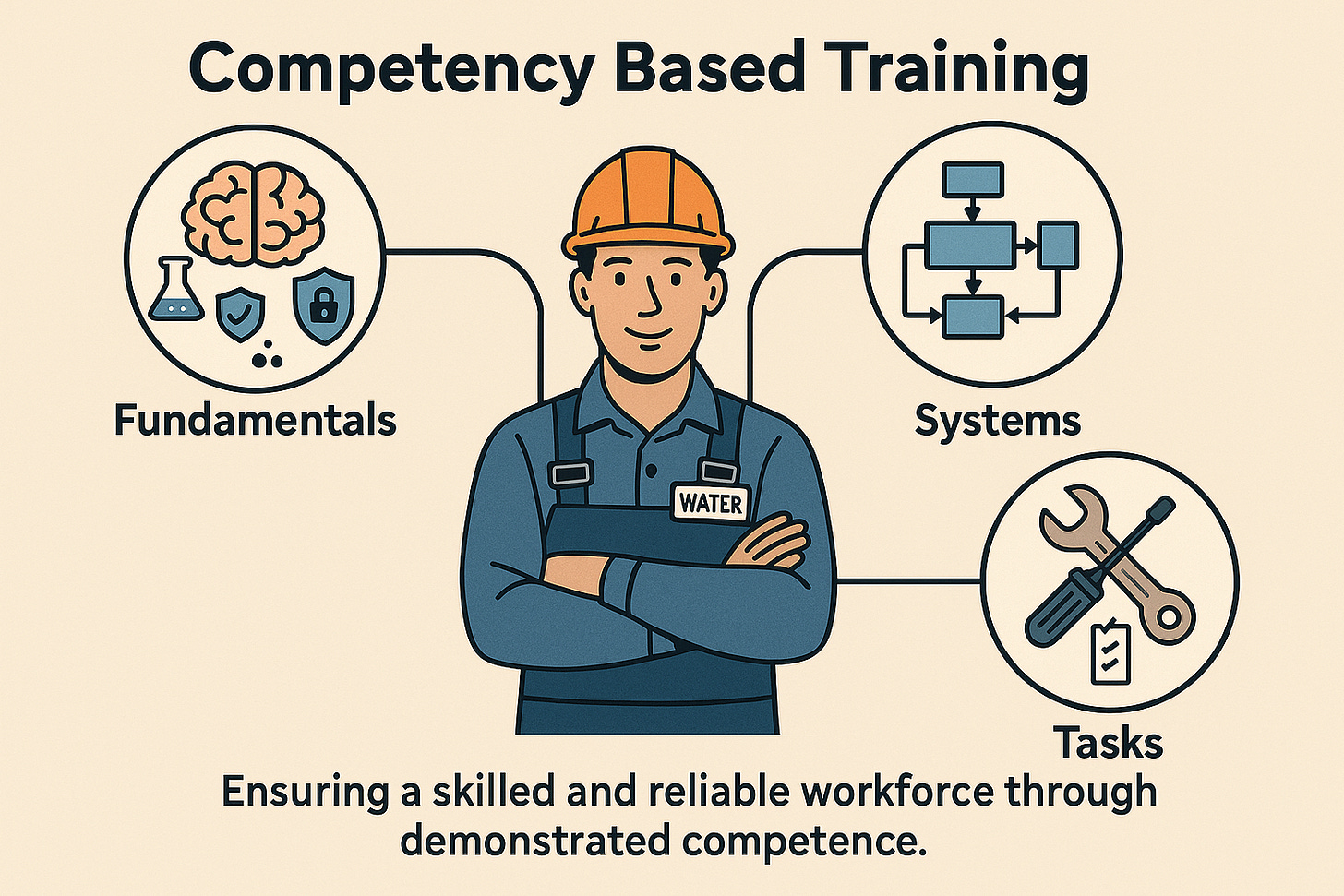

Rethinking How We Train: This entire idea is built on a stark reality: the water industry is facing a massive wave of retirements, a "silver tsunami." According to the EPA and industry analyses, as much as a third of the water workforce is eligible to retire in the next decade. This isn't just a loss of personnel; it's a catastrophic potential loss of unwritten knowledge. Decades of experience—knowing the quirks of a specific pump, understanding how the system responds in a storm—is at risk of walking out the door forever. To prevent this, creating a new worker requires moving beyond the outdated, one-size-fits-all training models of the past.

The new approach is multi-layered, built on a foundation of Competency-Based Training (CBT). This marks a fundamental shift away from older methods, whether it was the unstructured apprenticeship of watching a senior person and fetching a wrench or the more recent focus on simply tracking "seat time" in a classroom. The new focus is squarely on measuring demonstrated mastery of specific skills. In a CBT system, jobs are deconstructed into their core components: the "Fundamentals" (the underlying scientific principles), the "Systems" (knowledge of a specific piece of equipment or process), and the "Tasks" (the hands-on ability to perform a job function). This creates a clear roadmap for advancement, empowering workers to own their professional development and ensuring critical knowledge is systematically transferred.

Building on this foundation, the vision for training is becoming more contextual and on-demand. While not yet the norm everywhere, the path forward is clear: rather than pulling a worker off the floor for a week-long course, learning will be delivered at the point of need. In this near future, an operator wearing augmented reality glasses will see a digital overlay of a machine's internals while being guided through a complex repair. These same tools will allow procedures to be recorded from a first-person perspective, creating a library of best practices. This video footage can then be analyzed to refine the procedure itself for safety and efficiency, with the best examples edited into short video tutorials—a form of micro-learning—that a mechanic can pull up on their tablet. This approach respects the worker's time and creates a powerful feedback loop for continuous improvement.

Looking ahead, several key advancements will accelerate this transition. AI-driven learning platforms will act as personalized tutors, analyzing a worker's performance and automatically assigning micro-learning modules to shore up weaknesses. Fully immersive virtual reality simulations will allow teams to practice responding to catastrophic plant failures in a "safe-to-fail" environment, honing their teamwork and decision-making skills without real-world risk. These developments point to the future of training: a dynamic, intelligent, and deeply personalized ecosystem that builds expertise not just through instruction, but through experience.

A Collaborative Work Environment: This evolution in training doesn't just create smarter individual workers; it enables a fundamental shift in how they work together. This new worker doesn't operate in a silo. Collaboration is happening on multiple levels, from the regional to the individual. At the macro level, cross-agency consortiums are becoming essential. The challenges of workforce development and infrastructure maintenance are too large for any single organization to handle alone. In California, for example, we see this collaboration in action through a web of interconnected agencies. Groups like the Bay Area Clean Water Agencies (BACWA) create a unified voice for dozens of utilities, allowing them to pool resources for regulatory compliance. Meanwhile, the Bay Area Water Supply and Conservation Agency (BAWSCA) coordinates regional water supply strategy. And of course, there's BAYWORK, the very organization that authored the "Digital Worker" white paper, which brings agencies together specifically to ensure workforce reliability. Professional organizations like the California Water Environment Association (CWEA) and the CA-NV Section of the American Water Works Association (AWWA) are the connective tissue for the workforce itself, providing standardized training, certifications, and career development programs that create a common language and skill set across the entire industry. These groups prove that by working together, agencies can tackle systemic challenges—from funding new infrastructure to building a new generation of talent—that would be impossible to solve alone.

But this powerful regional collaboration is only possible because of a parallel shift happening at the micro level, within the organization itself. The old culture often lionized the "cowboy"—the lone expert who could single-handedly solve any problem, but whose knowledge was kept in their head. That model is too brittle for the complexity of modern systems. The future belongs to connected, collaborative teams. New technology is the critical enabler of this shift, breaking down the physical and temporal barriers that create isolation. The night shift operator, once completely on their own when facing a critical issue, can now use a tablet or smart glasses to get a second set of fresh eyes from an on-call expert miles away. A journeyman facing a tricky, unfamiliar piece of equipment can use their glasses to show their supervisor exactly what they're seeing. The supervisor, in their ear, can walk him through the situation, providing guidance and preventing a costly mistake. This technology transforms individual knowledge into an on-demand, shared asset, building a more resilient and adaptable workforce that can collectively solve problems that no single entity—or single cowboy—could tackle alone.

The New Operational Model: The Click and Roll

When I started at my first treatment plant, my supervisor told me how, back in the 90s, they’d repurposed an old building automation system to get remote telemetry from critical chlorine sensors down the road. It sounds wild today—we don't take chances with critical data like that. But the story stuck with me because it highlights something essential about the people in these jobs. They’re smart, creative, and maybe a little crazy. There's a deep-seated instinct to tinker, to use tools in ways the manufacturers never imagined, and to ultimately get the job done. That same spirit that jury-rigged systems with steam and pneumatics, then electronics and digital controls, is now meeting artificial intelligence.

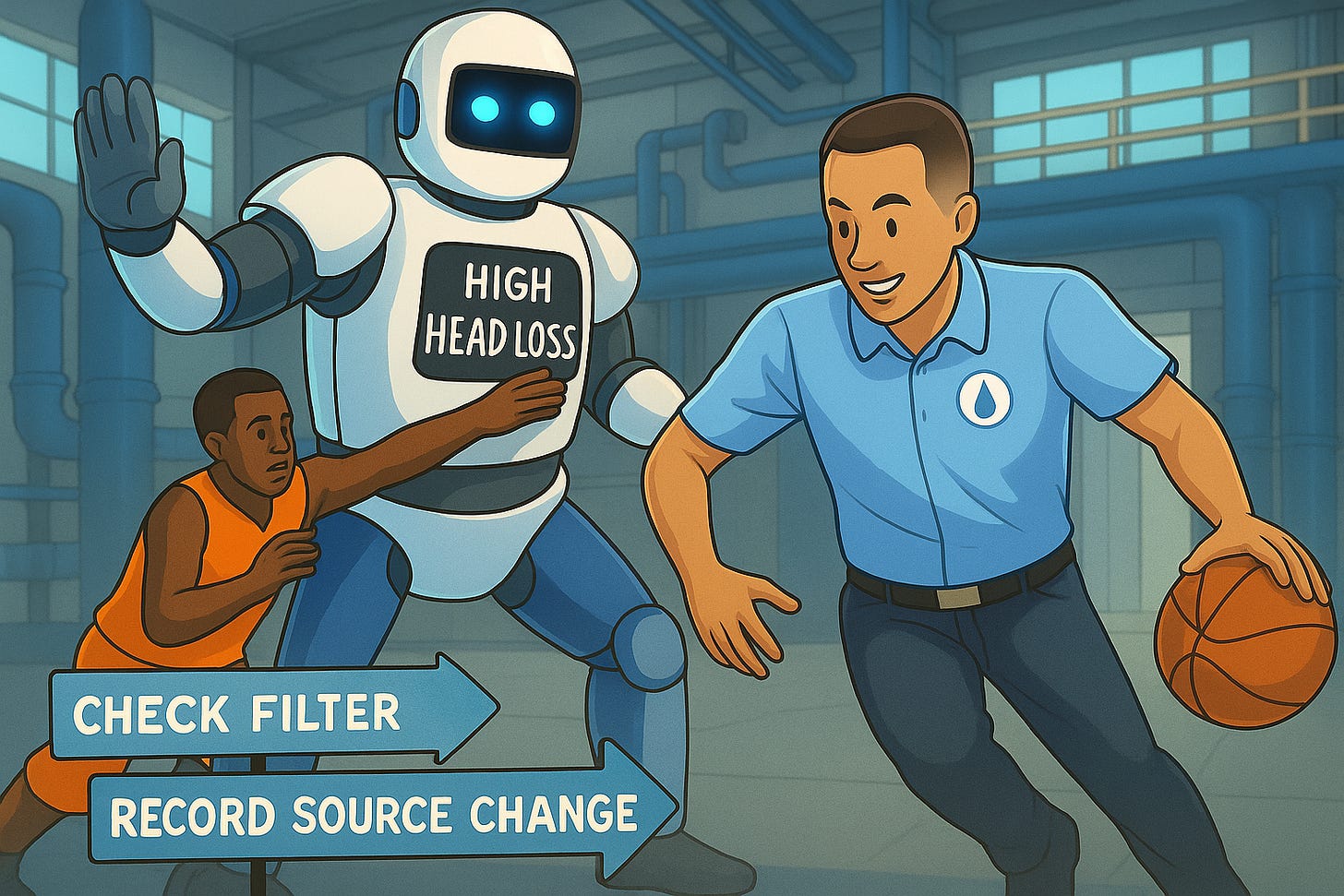

This isn't a conflict; it's a convergence. It's the meeting of two uniquely American forms of problem-solving: the hands-on and the high-tech. This innate adaptability is why the future isn't about replacement, but a powerful partnership. The blue-collar knowledge worker thrives within a new operational model that redefines the human-machine relationship. This isn't a top-down, automated system where the human is a passive observer. It's a dynamic, strategic partnership, best understood through a classic basketball concept: The Industrial Pick and Roll (or how about the Click and Roll, is that too cheesy? You know what, this is my blog. Click and Roll, baby!).

In a pick and roll, two players with different skills—a ball-handler and a screener—work in perfect sync to create an opportunity that neither could alone. It's a fluid, strategic play built on trust and shared understanding. In our industrial context, the human operator is the skilled ball-handler, and the AI is the powerful screener. It’s a system built on mutual contribution, not top-down instruction.

This partnership functions by seamlessly integrating two distinct but equally crucial forms of intelligence: The Screener (The AI), which screens out the noise from millions of data points to set the "pick" by flagging a potential issue; and The Ball-Handler (The Human Expert), who uses their contextual knowledge and sensory wisdom to "read the play" and decide on the best course of action. The AI creates the opportunity, but the human makes the play.

Of course, this partnership isn't always perfect. Sometimes the AI flags a sensor ghost, and sometimes a human misreads the play. But even the mistakes are valuable—they create data points that make both the human and the AI smarter for the next round. It's a system that learns from its failures, not just its successes.

And this "Click and Roll" is a continuous, reciprocal loop. Sometimes the AI sets the pick, flagging that "Filter Headloss on Filter Bed #2 is accruing faster than its 5-day average." The operator then reads the play. They might choose to "roll" by investigating the filter, checking backwash history and coagulant doses. Or, using their contextual knowledge, they might "reject the screen," knowing the plant just switched to a different raw water source. They log this information, and the system learns the correlation. But the play can also run in reverse. An operator can initiate the play by logging a faint, intermittent clicking sound that no sensor can detect. The AI then runs the offense, cross-referencing that observation with historical data to find a hidden pattern that predicts a future failure.

This pragmatic partnership is the key to modernizing our nation's infrastructure. The blue-collar knowledge worker is the human bridge between the new digital layer and the old physical iron, and their job is secure precisely because an AI alone cannot navigate the messy, complex, real-world patchwork of old and new systems.

From Blueprint to Reality: The Path Forward

The rise of the Blue-Collar Knowledge Worker and the "Click and Roll" operational model isn't science fiction. Its foundations are being laid today with current technology, but widespread adoption isn't guaranteed. The path forward depends on navigating real-world gaps and making strategic choices about technology, training, and collaboration.

The "Today": Grounding the Concept in Reality

This evolution is already happening, powered by a mature ecosystem of accessible technologies. We see it in the deployment of robust Enterprise Asset Management (EAM) systems—like IBM's Maximo, Infor EAM, and SAP Plant Maintenance—that digitize workflows and maintenance schedules. We see it in augmented reality (AR) platforms for remote assistance, where industrial-grade wearables from companies like RealWear and Vuzix give frontline workers hands-free access to information, not just Microsoft's HoloLens. This is all stitched together by mobile workforce software and ubiquitous enterprise collaboration platforms that connect field operators to central command in real time.

This isn't just theory; it's being put into practice. We see the collaborative spirit in a growing number of initiatives across North America. National organizations like the Water Environment Federation (WEF) and the American Water Works Association (AWWA) have programs focused on developing the next-generation workforce. These are complemented by innovative university programs and regional consortiums that prove the value of a coordinated, forward-looking approach to workforce development.

The "Tomorrow": Two Plausible Futures

When I look at the next 10-15 years, I see two ways this could go:

The Integrated Future: In this scenario, the Blue-Collar Knowledge Worker becomes the industry standard. Investment in training and collaborative technology creates a highly skilled, adaptable, and resilient national workforce. Infrastructure becomes more reliable, career pathways in the skilled trades become more attractive to a new generation of talent, and the U.S. emerges as a global leader in operational technology and human-machine teaming.

The Fractured Future: In this future, adoption is uneven. Only large, well-funded urban utilities successfully make the transition. Smaller, rural, and under-capitalized utilities are left behind, creating a dangerous "digital divide" in critical infrastructure. This leads to increased fragility in in essential services, widens the economic gap between regions, and makes the nation's infrastructure only as strong as its weakest link.

The Gaps: Barriers to a Better Future

The difference between these two futures will be determined by our ability to close three critical gaps:

The Investment Gap: The high upfront cost of new technology and comprehensive training programs is prohibitive for smaller organizations, creating the risk of the "Fractured Future."

The Skills Gap: Our traditional training systems are failing to unlock the full potential of our workforce. They weren't designed for the digital-physical workplace, leaving a gap between the inherent ingenuity of our people and the powerful tools now at their disposal.

The Cultural Gap: From where I stand, this is the one that really keeps me up at night. It's the institutional inertia, the risk-averse culture that can stifle the very creativity and tinkerer's spirit that has always been the industry's greatest asset. It's the "that's not how we do it here" mindset that can stall even the most promising pilot programs. (if you read this and thought "path dependence," you are my kind of people. Yes, I will be definitely writing more about this problem.)

The Path Forward: Enabling the Next Generation

Closing these gaps requires intentional, coordinated effort at every level. It's not just a technological challenge; it's about investing in our people, plain and simple. The path forward requires a focus on tangible, scalable initiatives:

A national commitment to modernizing vocational education. This has to go beyond talk. It means creating tangible programs like a "Digital Trades Grant," mirroring federal grants for STEM, but aimed squarely at community colleges and trade schools. These grants would fund the development of new curriculum that treats data literacy with the same seriousness as mechanical skill, and build out the AR/VR training labs needed to teach it.

Accelerating the development of collaborative consortiums. We need to replicate successful models. Look at BAYWORK, a network of water and wastewater agencies in the San Francisco Bay Area focused on workforce reliability through regional collaboration. There, dozens of utilities, large and small, pool their resources. They don't just share the cost of a training simulator; they create standardized job descriptions, run joint recruitment efforts, and build clear, regional career pathways. This approach lowers the barrier to entry for smaller organizations and builds a more resilient regional workforce. We need a hundred more of those.

A deep organizational commitment to a new way of working. This is the hardest part. It means leaders must actively champion a culture of innovation and trust. It means budgeting for the Modernized Training Paradigm and creating new roles that bridge the gap between IT and operations. It means empowering workers with the tools and the autonomy to experiment, ensuring that American ingenuity is amplified, not automated away.

Ultimately, the choice is ours. The technology to create a more resilient, efficient, and engaging future for the skilled trades already exists. The determining factor will be our willingness to invest in the human at the center of the system.

Acknowledgments: I'd like to extend a special thanks to Catherine Curtis from BAYWORK and the SFPUC. Her professional guidance at the SFPUC is invaluable, and her tireless work on behalf of BAYWORK and the entire water industry continues to be an inspiration.

What does this "Click and Roll" model look like in your field? Where do you see the partnership between human expertise and AI creating the most value?